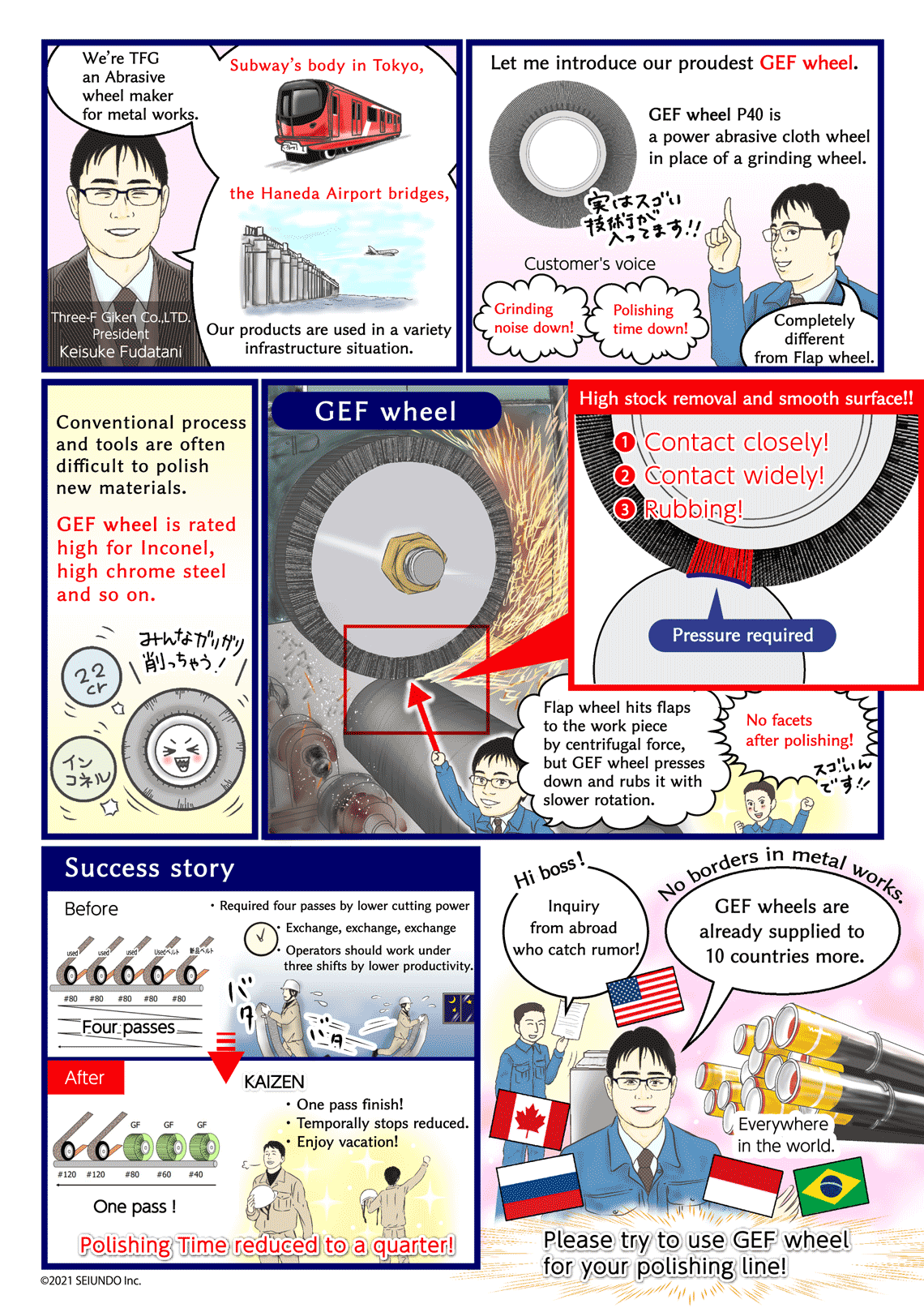

What's GEF Wheel

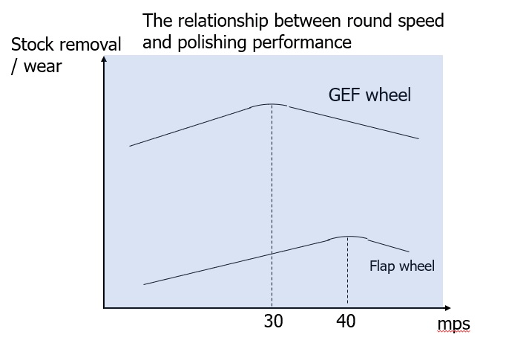

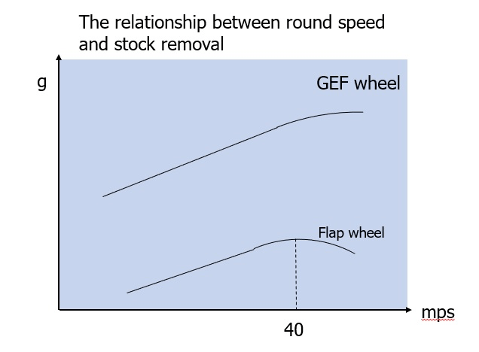

GEF wheel is high-density abrasive cloth wheel that is manufactured with our patented technology. Typical abrasive cloth wheel (Flap wheel) grinds by hitting workpiece with the wheel’s abrasive cloth flaps using the centrifugal force generated by rotation. The only way to improve grindability is to increase the rotation speed at which the abrasive cloth collides with the workpiece. However, no matter how fast the collision speed is increased, the edge of flaps dose not press down to the workpiece because there is no backup. Moreover, the greater the impact of collision, the greater the wear on the edge of flaps.

GEF wheel has densely attached flaps so that each flap has backup behind it. As a result, the flaps forced to the workpiece. This design has changed the motion of the abrasive cloth to rubbing instead of hitting. Since the edge of flaps press down well even when they are firmly applied, this increases the effect of the abrasive grains and results in a higher grinding performance than conventional Flap wheel. In other words, the flaps of the GEF wheel perform a completely different way from Flap wheel that uses centrifugal force to hit the workpiece.

Since the flaps of GEF wheel are densely compressed, it is necessary to apply sufficient pressure so that the edges of the flaps open properly. This may allow the abrasive grains to work effectively. The optimum peripheral speed of GEF wheel is 25 to 35 meters per second (90 to 110 feet per second) under wet condition. The faster the peripheral speed, the better the grindability, but at the same time, its centrifugal force makes the edge of the flap harder, which requires more pressure. The user must consider the motor output of the polishing machine to find a suitable rotation speed for the GEF wheel. If the relationship between the rotation speed and pressure is appropriate, the operator will be able to obtain the best performance of GEF wheel.

If GEF wheel is used under dry conditions, it may burn the surface of workpiece due to the frictional heat. If setting condition is not suitable, GEF wheel could be burnt by frictional heat storage.

The users should not think of GEF wheel as Flap wheel with enhanced grindability. GEF wheel does not have some of the peculiar features of Flap wheel. For instance, they cannot perform fuzzy grinding, smoothing from the previous polishing step, or be applied to shaped steel. GEF wheel should be regarded more like elastic grinding wheel.

The #40 to #80 grit sizes are recommended to make the most effective features of GEF wheel. After the pipe and tube making process, operators usually use abrasive belt grinding to remove flaws and then Flap wheels for finishing for many of these operators, it could be a burden on them to replace abrasive belts quite often. By replacing belts with GEF wheels, operators must be able to significantly improve the operating efficiency of polishing machines.

Operators who use grinding wheels after pipe and tube making process can use GEF wheel #40 instead of grinding wheel #40. In addition, by replacing the grinding wheel with GEF wheel, the frequency of the grinding noise is lower than that of grinding wheel, he would no longer be disturbed by the annoying noise.

Coarser grinding wheel makes so many facets on the surface of pipe or tube. In contrast, GEF wheel provides a smooth finish similar to that of conventional abrasive belt. If you look at the picture at the top page of this website, you can see GEF wheel fits the shape of the pipe well.

GEF wheel is the unique abrasive cloth like no other wheel in the world.

Please feel free to contact us if you need a GEF wheel with specifications different from the standard type shown on the website. GEF wheel can be adjusted in hardness upon customer's request.

If you understood and utilize them properly, GEF wheel can enhance processes, increase productivity, and reduce costs. We aim to provide our customers with innovative abrasive cloth wheels that can contribute to the development of industries.